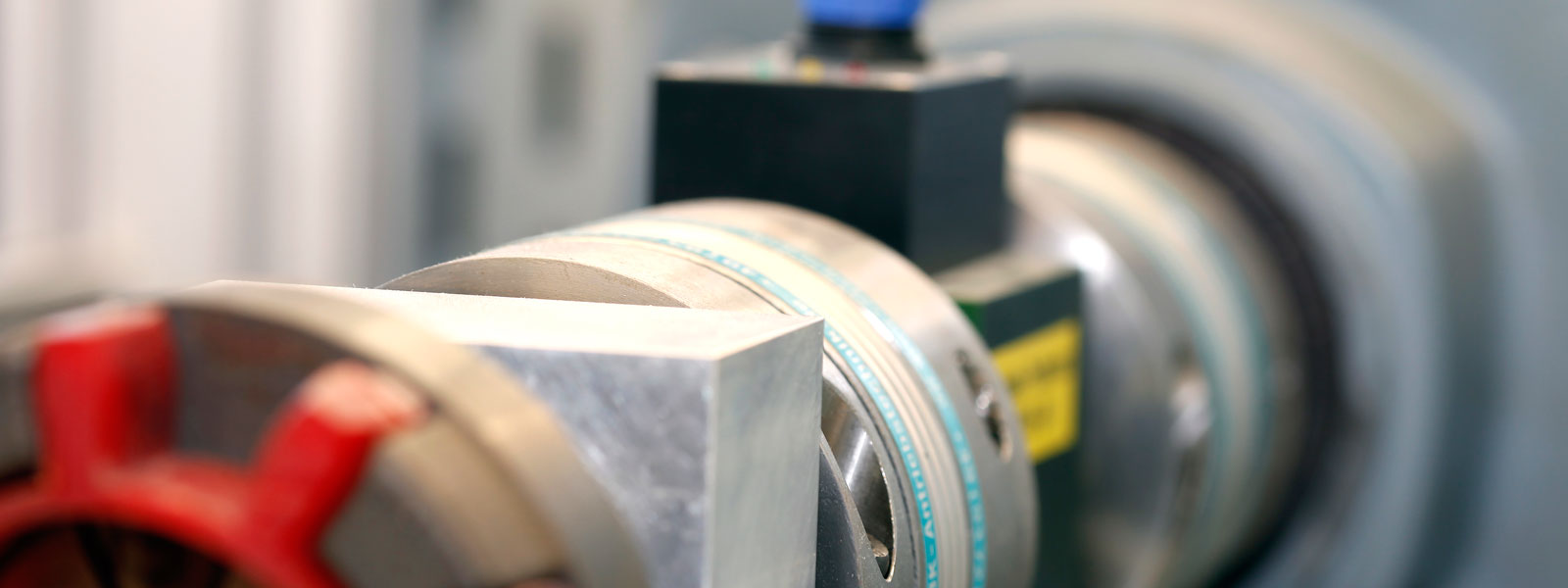

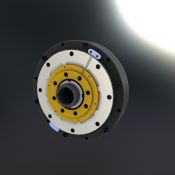

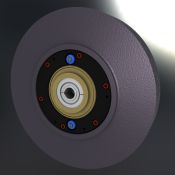

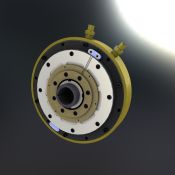

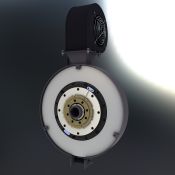

Magnetic particle clutches and magnetic particle brakes

performance size from 0,2 Nm up to 1000 Nm

The magnetic particle clutch respectively brake achieves at a low driving power a high torque being independent of slip speed. It distinguishes itself by a simple structure, low weight and requires little room.

This advantage makes it possible for the clutch resp. brake to be employed in the solution of many technical problems. Appropriate regulation and control devices - as for ex. our LIEDTKE Controller - are needed for the different applications.

Application:

- unwinding brakes/winding

- torque controls

- torque limitations

- speed controls

- clutch proceedings

- start controls

The characteristics of the magnetic particle clutches and brakes are a great advantage in control engineering. By changing the intensity of the exciting current, the torque to be transferred can be adjusted within the range of about 1:50.

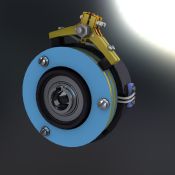

Magnetic particle clutches are available with solid shaft and without slip ring transmitter for a range from 0,2 to 5 Nm (Type EFAS) applicable as clutch or brake.

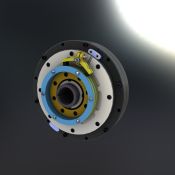

The models with hollow shaft and slip ring transmitters are available for the range from 2 to 1000 Nm, with or without heat sink (Type ERA or Type EAT) depending on how much power is lost by customer application.

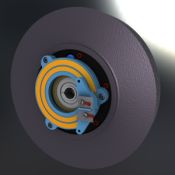

Click on pic will grow the view

Magnetic particle brakes are available with solid shaft for a range from 0,2 to 5 Nm (Type FAS).

The models with hollow shaft are available for a range from 2 to 1000 Nm, with or without heat sink (Type FAT or Type FRAT) or with water cooling (Type FRATO) depending on how much power is lost by customer application.

The standard types are destined for horizontal shaft mounting only.

If vertical shaft mounting is required or if rotation speed <= 40 min-1 is desired, types with remanent rotor (app. "RR") must be installed.

This variant is available in nearly all sizes.

In this version the amount of rest torque is nearly two times as high as in the standard models.

Brakes with heat sink in nearly all sizes can be fitted with external fans.

For more product information, click here.